Not All Steps Are Created Equal

Installing stair treads has never been an easy part of the flooring industry, as it can be quite challenging and time consuming for the professional requiring a more focused approach toward attention to detail. In a perfect world every stair constructed would be an exact copy of the one above and below making measuring and cutting rubber stair treads and other stairway materials a measure once and cut all the same size a simple process, unfortunately that’s not the case. Each stair has its own slightly different angles, and discrepancies do to many common factors, such as materials used, and construction conditions. A professional installer knows this and will never measure once and cut all to the same size.

Instead professionals know to approach each step individually which is a time consuming process. With the high cost of each tread the professional must pay close attention in order not to make a mistake. One process is done by creating a cardboard template and skillfully marking the edges of each individual step. This process can be time consuming and requires a certain level of skill to become professionally accurate! Homemade wooden jigs are sometimes made with left and right independently adjustable edges. Still, this technique is also time consuming and not perfect either due to jig play as well as most step sides not being perfectly straight and square. With each rubber floor tread needing to be perfectly matched to each step there is little to no room for error. Any unacceptable gaps can over time collect dirt and water from the cleaning process and subject the tread to loosen and hasten the treads to fail with the need to be re-adhered or even replaced.

Treadman – A tool designed and engineered for the stair tread installation profession.

With several stair tread challenges in mind Proknee Corporation has developed a tool specially designed for the stair tread installer. Treadman, a tool that will cut your installation time in half or more and give you quick and accurate measurements thus eliminating the chance of costly mistakes.

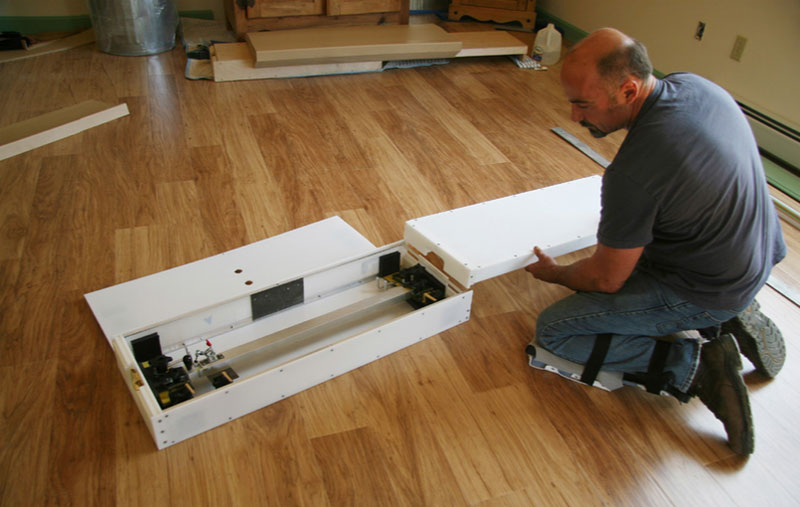

What makes Treadman unique and an invaluable tool for the stair tread installer is its design and function that gives the novice as well the seasoned professional, quick, accurate settings and perfectly cut stair treads that confirm to the most difficult of steps you may come up against. Treadman is a portable light weight tool weighting 6-1/2 lbs. Our standard unit won’t leave you fatigued by the end of the day carrying it back and forth to the stair way.

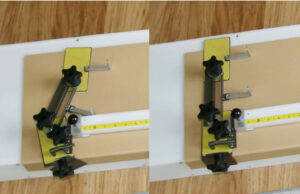

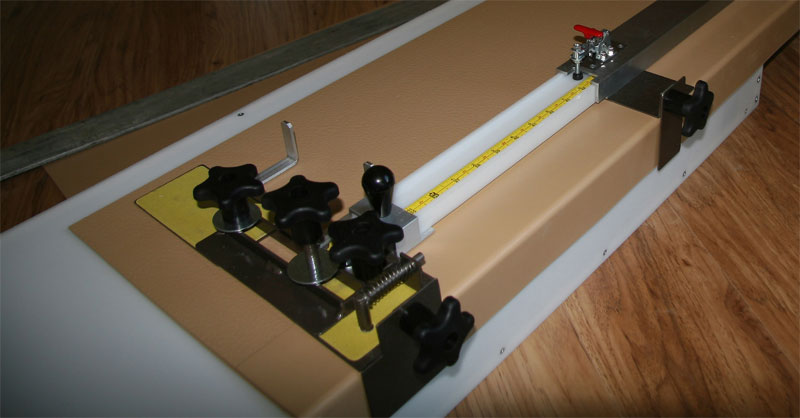

Treadman Quickly adjusts and conforms precisely to each individual step and securely locks in your steps and treads specific size and identical dimensions that you will be cutting your tread to. Treadman acts as your template and your cutting guide. Made up of 1/16” steel plates and built to withstand a lifetime of cutting. With large easy to adjust knobs and spring loaded edge plates Treadman makes your next measurement as quick and easy as your last. Treadman’s standard unit has the ability to expand in depths from 10” to 13-1/4” and in widths from 35-1/4” to 61-1/2 “, and with three other optional extension kits the widths ranges will expand from 22-1/2” up to 9’-1/2”! Treadman’s rubber stairtread thickness gauge automatically adjusts from 1/32” to 1/4”. The optional self storage carry case is constructed from blade friendly high density polyethylene which expands and doubles as a sturdy heavy duty cutting surface specifically designed to cut and handle rubber stair treads. An overall cutting surface of 13-1/2” x 6’ 3-3/4’ with a 1-7/8” vertical surface is provided for cutting nosing’s.

With very little practice and time you will have mastered this tool which in turn reward the professionals with time savings and results of perfection.

For a more in-depth look and detailed instruction you can see Treadman® in action on youtube.

Treadman® Technical Specifications

- Wall plates adjust to step depths from 10” to 13 1⁄4”

- Standard unit adjusts from step widths of 35 ¼” to 61 ½”

- Extension Kit 3 adjusts from step widths of 22 ½” to 36”

- Extension Kit 2 adjusts from step widths of 6’ 10 3⁄8” to 9’ ½”

- Extension Kit 1 adjusts from step widths of 4’ 8 7⁄8” to 6’ 11”

- 1 piece Step/Riser Template Kit captures riser heights from 6” to 8”

- Rubber stairtread thickness gauge automatic adjustment from 1⁄32” to ¼”

- Standard unit weighs 6 ½ lbs

- Adjustment bar sub-assemblies made from self-lubricating,high density, polyethylene

- 1⁄16” thick steel marking/cutting guide plates with ¼ / 20 welded steel threaded studs

- 1st plane left and right adjustment plates use factory preloaded spring assemblies

- Sand finish powder coating on all metal sub-assemblies

- Main frame assembly constructed from 1” x 2” x 1⁄8” aluminum tubing

- Fully adjustable nose plates capture angles from 82° inward to unlimited on vertical nose plane

- Fully adjustable wall plates capture 76° inward to 96° outward on horizontal step plane

- Plate adjustment knob heights differentiation of 5⁄8”

- Tool Box dimensions closed 13 ½” x 38 ¾” x 6 ½”

- Maximum cutting surface of 13 ½” x 6’ 3 ¾” with a 1 7⁄8” vertical surface for cutting nosings

- Tool Box constructed from blade friendly high density polyethylene

- Weight of Tool Box without tool is 23 lbs

Treadman® FAQ

Q. Can Treadman only be used on rubber stairtreads?

A. Treadman can be used to both mark and cut rubber stairtreads, however, it can also be used to mark other types of materials like Hardwoods, Tile, Ceramics or any hard surface material.

Q. Should I purchase the Treadman Tool Box/Cutting Block? What are the benefits of having it?

A. We highly recommend that you purchase the Tool Box/Cutting Block. The box is not only a safe storage container, it also makes it easier to transport the Treadman tool and can be used as a cutting surface to cut rubber stairtreads. However, you can use the Treadman tool without it.

Q. Can you use the Treadman to complete One Piece Step/Riser installations?

A. Yes, but you will need to purchase the One Piece Step/Riser Template Kit.

Q. Does the Treadman come with instructions so I will know how to use it?

A. There are no written instructions, however, we have videos on our website that give demonstrations on both how to use the Treadman tool and also how to complete One Piece Step/Riser installations. You can also view the videos on YouTube – Search Mr Proknee.

Q. Can I return the Treadman if I don’t like it or decide it is not for me?

A. We offer a 30 Day Money Back Guarantee if the Treadman is returned in NEW AND UN-USED CONDITION. We recommend that you look over the tool, and view the instructional videos on our website or on the included DVD BEFORE using the tool on a job. If you need to return your Treadman, call us at 877 776 5633 to obtain a Return Authorization Number. We will issue a refund once the Treadman is received and evaluated by our Return Department.

Q. What kind of warranty does ProKnee offer on the Treadman?

A. We warranty the Treadman for ONE YEAR FROM DATE OF PURCHASE on all parts. If you feel you have a warranty issue, contact us at 877 776 5633 to receive a Return Authorization Number. You will need to send the Treadman into our Repair Facility for evaluation. We will either fix or replace any parts that we determine are covered under the warranty and ship the Treadman back to you.

Q. What size stairtreads can the Treadman be used for?

A. The Standard Treadman tool can do stairtreads from 35 1⁄4″ to 61 1⁄2″ in length. If you have stairs that are shorter or longer, we also have 3 Extension Kits that can be purchased separately – that will allow you to complete installations on treads from 22 1⁄2″ to 9′ 1⁄2″!